Alternative Feeds for Beef Cattle

On most cattle operations, feed represents the largest single variable input cost. Livestock producers continually examine ways to reduce this cost and explore options to efficiently and safely feed their livestock. While hay, pasture, other forages and grains make up the largest component of livestock feed, there are many alternative feeds that can supplement and even improve the diet. Cost effective procurement of non-conventional feeds can increase profitability across the operation. When faced with reduced supplies of good quality hay due to declining production acres and weather events such as late spring frosts, excessive rains or drought, many producers seek alternative feeds for their livestock. While these alternative feed sources can offer flexibility and low-cost options, feed testing and advice from a livestock nutritionist is recommended to ensure nutritional requirements of the type of cattle being fed are being met.

Alternative feedstuffs can provide an economic benefit to a feeding program, but some investigation is needed to ensure there are no unintended consequences. All feed ingredients approved for use in food-producing livestock are posted and updated regularly on the Canadian Food Inspection Agency website.

| Key Points |

|---|

| The inclusion of alternative feeds in a ration or feeding program can potentially reduce feed costs and stretch feed supplies, while maintaining nutritional requirements of cattle |

| When sourcing and adding non-conventional feeds to the ration, consult a livestock nutritionist to obtain the best advice for ration balancing. Conduct feed tests for each feed source |

| Test for nitrates and sulfate when feed sources have been stressed by drought or other factors. Because of additive effects, also test water sources for nitrates and sulfate |

| Supplementation is often required when feeding non-conventional feeds, as they can be low in key vitamins and minerals, or contain certain minerals in high amounts which can lead to an imbalance |

| When adding alternative feeds into a ration or feeding program, always make changes slowly to allow the cattle to adjust to the feed |

| Conduct feed tests on heated grains prior to feeding to cattle |

| Alternative feeds require careful management to ensure that they meet the nutritional needs of the cattle. Supplemental protein, energy or fibre sources may be necessary to create a balanced ration |

Factors to Consider

Alternative feeds can include crop residues, damaged crops, processing by-products, fruit, vegetable and bakery waste, off grade grains and even weeds. Resourceful producers will consider several factors when sourcing alternative feeds:

- cost of feed

- cost of transportation

- storage of feed including special bins, silos, or conditions to reduce spoilage

- nutritional value of feed including any deficiencies or toxicity that must be corrected

- consistency and ongoing availability of feed

- ease of integration into operation, such as special feeding management, grinding, or mixing equipment required

- palatability of feed and acceptance by livestock

Cattle are natural recyclers and with properly balanced nutrition, can use many non-conventional, by-product or alternative feeds.

The inclusion of alternative feeds in a ration or feeding program can reduce feed costs and stretch feed supplies, while meeting nutritional requirements. Weather events such as drought, flooding, late spring frosts or hail can impact conventional feed supplies and increase prices. Many producers incorporate non-conventional feed sources into their rations to reduce costs and reliance upon hay or silage. While non-conventional feeds can be a cost-effective choice, producers will need to compare the actual costs of each feed source, along with transportation and storage to determine viability. A calculator for evaluating the relative economic value of feeds based on protein and energy content is available to assist producers when making these decisions.

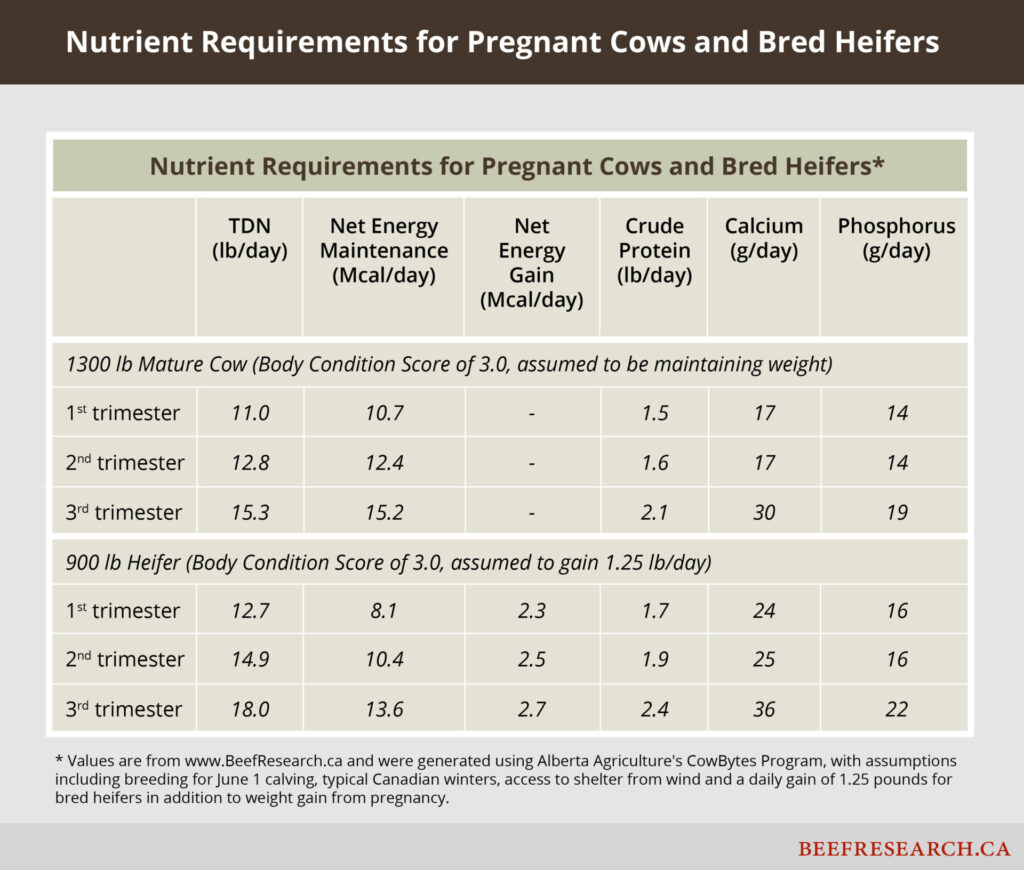

Cattle require appropriate levels of energy, protein, fibre, vitamins and minerals to allow maintenance, growth, reproduction and gestation, milk production, and to support the immune system. When sourcing and adding non-conventional feeds to the ration, consult a livestock nutritionist to obtain the best advice for ration balancing. Conduct feed tests for each feed source. Balance nutrient requirements for the sex, age, body condition and stage of production of the cattle being fed. For example, straw can be a low-cost alternative feed, however, it requires supplementation with additional energy, protein and minerals to provide adequate nutrition for all classes of cattle.

Supplementation is often required when feeding non-conventional feeds, as they can be low in key vitamins and minerals, or contain certain minerals in high amounts which can lead to an imbalance. Vitamins A, D and E are required for metabolism, reproductive efficiency and proper immune function. Macrominerals include calcium, phosphorus, sodium, chlorine, magnesium, potassium and sulphur. Calcium and phosphorus are major components of the skeleton, as well as impacting efficiency of gain and lactation. Magnesium is required for nervous system function and metabolism. Imbalances between calcium, phosphorus and magnesium can cause grass or winter tetany. Microminerals, required in lower amounts, include cobalt, iodine, copper, manganese, zinc and selenium. Many interrelationships exist between the various macro and microminerals that can create excesses or deficiencies. Generally, trace mineral fortified salt and at least a 1:1 mineral (equal parts calcium and phosphorus) will be required. When utilizing greenfeed, straw, or lower quality slough hay, additional calcium may be required, with a calcium to phosphorous ratio of 2:11.

Testing and analysis are very important for these non-conventional feeds. Consulting with a livestock nutritionist or specialist can be helpful when interpreting feed test results. Using alternative feeds in a ration can require some additional management and will require monitoring cattle for signs of potential problems, including higher or lower levels of certain minerals.

Laboratories that conduct feed analysis report on several key parameters. These include moisture content, crude protein (CP), total digestible nutrients (TDN) which measures energy, fibre (NDF and ADF), and some vitamins and minerals. These basic reports will indicate the levels that the feeds contain and will help a nutritionist design appropriate rations. Additional tests can be requested to determine the presence of toxins and nitrates which can be dangerous to cattle. These specialized tests are available at an additional fee and can be an important tool in avoiding problems, from low rate of gain, fertility and reproductive issues, to the worst outcome, death.

It is important to test for both nitrates and sulfates, especially when alternative feed sources have been stressed by drought or other factors. Sulfates and nitrate in water can have an additive effect and result in symptoms even if the concentrations in both feed and water are within acceptable levels. Feed with moderate levels of nitrates and sulfate can be diluted and safely fed to cattle. Work with a nutritionist to safely balance high nitrate or sulfate feeds.

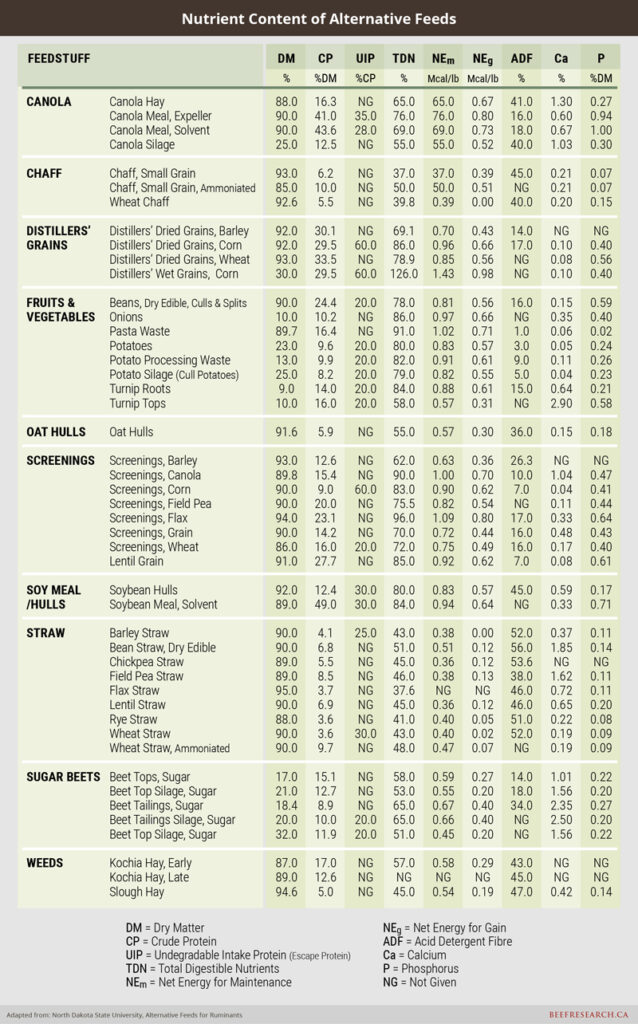

These key components are required in the proper balance to ensure nutritional needs of the cattle are met. More information can be found on the Feed Testing and Analysis page. The following table provides a brief summary of nutrient requirements.

Producers who are not working directly with a nutritionist to formulate rations can use a software program to assist with calculating the proper blends and rations. CowBytes, a software program available through the BCRC, allows producers to input feed analysis, costs and calculate appropriate feed rations that safely use the alternative feed sources.

When adding alternative feeds into a ration or feeding program, always make changes slowly to allow the cattle to adjust to the feed. Sudden changes to their diet can create digestive problems and negatively impact rumen health. Consistent dry matter intake is one of the key factors in maintaining rumen health, and when it varies, the nutrient intake for microbes within the rumen changes. This can impact how nutrients are absorbed and how they are used by the cattle. Acute and subacute acidosis can occur when cattle consume feed that is high in fermentable carbohydrates, such as with grains, potatoes or sugar beets, especially when cattle are switched suddenly from low-energy forage-based diets to high-energy forage, grain, or carbohydrate diets. Ensure that the diet contains adequate amounts of fibre and that changes are made slowly over several weeks; allow a step up or transition period to acclimate cattle to the new feed source or additive.

Types of Alternative Feeds

Canola – Greenfeed, Hay, Meal, Silage, Straw

Canola, used as greenfeed, hay, meal or silage offers producers several alternative feed options. When cut in late bloom or early pod stage, crude protein averages 15% and total digestible nutrients (TDN) can be as high as 60% which is similar in quality to alfalfa/grass hay1. The high moisture content of the crop can make it difficult to cure and bale. Canola meal, a by-product of expelling oil, is high in protein (around 36%), energy (TDN of 68%)1, and essential amino acids. Canola straw has little to no feed value, with less than 4% crude protein, and 20% TDN2.

Benefits

Opportunities exist for livestock producers to procure canola hay, greenfeed, meal, and screenings. These various canola by-products that can be used as alternative feeds have high crude protein and energy. The significant acres devoted to canola have created more research on how by-products from crops including canola can be used in livestock feeding systems.

Drawbacks

Cattle may take several days to become accustomed to the taste of canola. Since canola is generally fertilized for high yields, it can contain high levels of nitrates and sulphur. High oil content (over 7%) can impair rumen function, reducing voluntary intake3. Drought stress in canola can lead to nitrate accumulation, as well, green canola regrowth that has been under moisture stress can be toxic to cattle4. Canola contains high levels of sulphur, which can lead to polioencephalomalacia (PEM).

Most suitable for:

All classes of cattle.

Chaff

During harvesting of crops, chaff can be collected and dropped onto straw swaths, or collected in a chaff wagon, pulled behind the combine and dumped into piles on the field. Chaff is a light, bulky, fibrous feed source, that is low in protein and energy. Cereal chaff is between 4-6% crude protein, while lentil and pea chaff are slightly higher at 7-9%. Energy is low for both cereals and legumes, with a TDN range between 30-50%. Supplementation will be required to provide sufficient nutrition. There is variability in chaff sources due to combine settings and efficiency, crop type, and time of harvest. Feed tests will be necessary to determine additional energy and protein requirements5.

Benefits

Chaff can be collected during combining and fed in the field where the piles are deposited. It can be mixed into rations to add fibre. Certain combines allow more grains, seeds and hulls to pass through during harvest, creating chaff with slightly higher feed value.

Drawbacks

Chaff is bulky so transportation costs are high if it is hauled off the field and stored in a feed yard. It is a poor source of both energy and protein.Collecting chaff requires extra machinery.

Most suitable for:

Mature, dry cows, as part of a balanced ration. Chaff can assist producers in stretching feed supplies, but may be best suited for mature cows, rather than young, growing animals that require more energy and protein.

Crop Residue

After harvesting crops, residues often remain that can be used for feeding cattle. This could include regrowth, shelled grains, or stubble and swath residue that can be grazed directly. In cases where sufficient plant matter remains, such as field pea or corn stover, baling is also an option. Permanent or portable electric fencing provides opportunities to turn cattle out to graze crop residues post-harvest and can be a low-cost way to use a potential feed source left in the field. Cereal crop residues are generally high in fibre, low in crude protein (3-4%) and have low digestibility. Grazing soybean or lentil residue can provide higher protein with the unharvested pods or shelled beans. Regrowth of cereals or pulses can provide an excellent quality feed source. Pulses, which are harvested earlier than cereals, may have significant regrowth prior to freeze-up. There is significant variability in protein and energy content of these feeds; testing is recommended.

Distillers’ Grains, Dried Distillers’ Grains

Distillers’ grains,dried distillers’ grains (DDG), distillers’ grains with solubles (DGS) and dried distillers’ grain with solubles (DDGS) are by-products of grain-based ethanol production which can provide an alternative feed source for producers within close proximity to production sites. Cereal grains such as corn, wheat and sorghum are heated and fermented to produce biofuels. The starch is converted and removed, leaving a concentrated protein, fibre, and oil mixture called distillers’ grains (solid residue) and thin stillage (liquid fraction). This mixture can be sold as wet distillers’ grains (WDG) or dried further into dried distillers’ grains (DDG). The thin stillage is often concentrated, added to the distillers’ grains (DGS) and dried into dried distillers’ grains with solubles (DDGS).

There is considerable variation in the composition of distillers’ grains due to the nutrient composition of grains used and the processing method; however, distillers’ grains can be a high source of protein (25-40%), a moderate source of digestible fibre (22-48%), a moderate source of fat (3-11%), and a high source of total digestible energy (80-90%)6.

Benefits

Distillers’ grains are highly palatable and can stimulate rumen activity. They can be an economical way to increase protein in feedlot rations and can increase growth rate and feed efficiency. The expansion of the North American grain-ethanol industry has created more opportunity for producers to access this feed source.

Drawbacks

Distillers’ grains are bulky in both wet and dried forms and proximity to processing plants determines the economics of using this feed. Some feed value can be lost during the drying process.

The high moisture content of wet distillers’ grains can limit their use in certain rations, such as feeding with silage. Warm weather will accelerate spoilage, so storage times should be limited to one to two days in summer and two weeks in winter. Longer term storage can be possible if dry products such as oat hulls or soy hulls are incorporated, and the mixture is ensiled.

Variability can occur between batches or loads; therefore, feed tests should be conducted on every load to determine nutrient content. DDGS can contain high levels of sulphur, which, if fed at over 40% of the diet, may increase the risk of polioencephalomalacia (PEM) in cattle, as this factsheet explores.

Although distillers’ grains contain fibre, the particle size of this fibre is too small to provide the “scratch factor” needed to stimulate rumen activity. Consequently, distillers’ grains should be viewed as a concentrate ingredient rather than as a fibre source to replace silage or other forms of roughage in the diet.

Most suitable for:

All classes of cattle, particularly feedlot cattle.

40% wheat DDGS (left) and 40% corn DDGS (right). Photo credit to Lee-Anne Walter.

Greenfeed – Cereals, Beans, Lentils, Peas

Cereals such as oats, barley and durum can be seeded, cut and baled as greenfeed. Energy and protein levels will vary with timing of harvest. Cereals cut in the boot stage, generally yield higher protein levels of up to 15%, while greenfeed cut later in the milk, soft dough or firm dough stage generally has lower protein levels, with slightly higher energy of 61% TDN and higher yields. Legume, pea and bean hay cut as greenfeed can be a cost-effective feed that provides close to 14% protein and 56% TDN for energy. Lentil and pea greenfeed cut in early stages provide similar nutrition to alfalfa. Quality will vary depending on stage of maturity and pod development, as well as any additional weather events which occur once it is swathed.

Conduct feed tests and consider additional tests for mycotoxins, nitrates or moulds. While some producers seed greenfeed as part of their planned feed strategy, this alternative feed may become available to opportunistic livestock producers following a weather event such as a hailstorm. Cash crop farmers who realize that the crop will not mature following the damage may be willing to sell the crop in the field to get it removed and avoid spraying out or tilling under.

Benefits

Greenfeed is higher in nutritional value than straw and can offer an economical alternative to hay.Storage requirements are the same as other baled forages, so no additional harvesting equipment or storage facilities are required. Bales can be rolled out, fed in bale feeders or put through a processor, so there is flexibility in feeding systems.

Drawbacks

Challenges include harvesting the crop if it has been badly damaged by hail, increased risk of disease and/or moulds, and dry down time once swathed. Cereal crops, if harvested after a weather event, such as hail or drought can be susceptible to nitrate accumulation. Cereal greenfeed tends to be low in magnesium and calcium and may accumulate excessive levels of potassium. Rations require monitoring and the possible use of a 2:1 or 3:1 calcium to phosphorous ratio mineral blend. Lentils, peas and soybeans cut as greenfeed take longer to dry down than other forages due to the pods and vegetative matter. Quality varies depending on stage of maturity and pod development.

Most suitable for:

All classes of cattle.

Fruit and Vegetable Waste and By-products

Cull fruits and vegetables are bulky, high moisture waste products of food manufacturing that can be incorporated into livestock rations. With these products, there is often high energy and high variability, requiring careful management and supplementation to balance rations. The high moisture levels increase risk of spoilage or freezing, therefore these products must be fed out quickly unless ensiled. Availability is highly regional and supply can also be variable. In some regions cull potatoes are often available and can be a high carbohydrate alternative feed used in place of grains. Potatoes are low in fibre, protein, vitamins and minerals, so supplementation is likely required. In New Brunswick alone, up to 135 million tonnes of cull potatoes are available annually7.

Benefits

Food waste products and by-products of processing can be a cost-effective means to add energy to the ration, depending on price and transportation costs. Use of these products can divert them from landfills, providing an environmental benefit.

Drawbacks

Transportation costs are high due to the bulky nature of the feed. Special storage and handling is required. Some vegetables, such as potatoes, or by-products can be a choking hazard for cattle, so chopping or processing may be necessary. Palatability can be an issue. Fruit and vegetables must be incorporated slowly in small enough proportions to manage for this potential issue. It is important to ensure that enough protein and fibre is included in the ration.

Most suitable for:

Yearlings, feeders, dry cows.

Oat Hulls

Oat hulls are a by-product of the oat processing sector and have a nutrient content similar to cereal straw. They are high in fibre, low in protein, and have low digestibility. Grinding prior to shipping increases density but can also make the product more dusty. Oat hulls can be used with higher quality forage rations to stretch feed supplies.

Benefits

Oat hulls can be an economical source of roughage if transportation distances and associated costs are limited.

Drawbacks

Oat hulls are bulky resulting in higher transportation costs. They are dusty and low in nutrient content.

Most suitable for:

Feeders, dry cattle, when mixed into a ration with a wet feed source to control dust.

Screenings – Cereals, Canola, Pulses

Screenings are often available as a by-product of grain companies cleaning grains prior to shipment to end users. These screenings may include split grains, chaff, and dockage such as pods or fibrous materials. Feed companies often purchase these grain screenings to manufacture into a pelleted product (grain screening pellets or GSP). While the pelleted product ensures greater conformity from load to load, the cost also increases due to processing. Producers who are able to purchase screenings directly from grain companies and processors can often buy screenings at a low cost and, if freight costs allow, have them delivered to their operations for less than the cost of a pelleted product.

Cereal screenings can provide energy ranging from 60-70% TDN, with protein from 12-14% CP, with canola screenings providing energy up to 90% TDN and protein of 15% CP. Legume screenings can provide TDN of 75% and protein of 20%, which can augment a low-cost straw or low-quality forage ration. Research done on replacing barley grain in feedlots with wheat screenings showed that wheat screenings could be substituted for barley grain without adverse impacts on growth performance or profitability8. This can allow feedlots to reduce costs when wheat screenings are available at a discount to barley grain.

Benefits

Screenings are a palatable, cost effective source of energy and protein. They do not require special storage facilities or treatments. Extra processing, such as rolling or grinding is not usually necessary, as the screenings contain chipped and split pieces of grains.

Drawbacks

Variability and consistency between loads require feed testing to determine feed value. Screenings can contain weed seeds which can be spread via the cattle if on pasture. When particle size becomes very small, the risk of acidosis increases therefore limit screens to 50% in growing diets, and 25-30% in finishing diets9. Cereal screenings may pose a significant risk of ergot; which can develop during cool, wet springs and summers.

Most suitable for:

All classes of cattle.

This photo shows a mixture of lentil screenings including many cracked and split lentils as well as pods and hulls. A high protein source, it will mix well into a ration of straw and low-quality forage and provides a suitable level of energy. Photo credit, T. Carter

Soybean – Meal, Hulls

When soybeans are processed for oil extraction, hulls and meal are created as by-products. Hulls provide crude protein of about 12%, energy of up to 80% TDN and highly digestible fibre to the diet but are bulky and dusty; grinding decreases the particle size, increasing destiny for shipping. Hulls are high in calcium, but low in phosphorus. Because the fibre is highly digestible, soybean hulls cannot be the only source of fibre in the ration. When offered to livestock on pasture or with hay, uptake is good due to palatability and rapid gains can result1.

Soymeal is ground which facilitates digestion and has high protein and energy levels, often up to 49% CP and 84% TDN.

Benefits

Soybean hulls are a palatable source of energy, while soymeal is higher in protein. Both are good sources of energy and can be economical additions to a feed ration3.

Drawbacks

Soybean hulls and meal can be bulky, increasing transportation and storage costs. Nutrient content is highly variable. Soymeal must be used within three weeks of grinding to avoid spoilage causing rancidity or mould.

Most suitable for:

All classes of cattle.

Sprouted and Heated Grains

Wet conditions and weather challenges during harvest can result in high moisture or “tough” grains. These grains are at risk of heating or sprouting, presenting problems with safe, long-term storage. These grains are not suitable to enter human food supply and may become available to producers at a discounted price. While storage of these high moisture or sprouted grains can present challenges, data from several studies indicates little difference in nutritive value, average daily gain (ADG), feed to gain ratios, or carcass characteristics of cattle when fed sprouted grains. Additionally, in some instances, the nutrient levels in sprouted grains are higher due to the concentration effect that occurs during germination2. Heated grains can be at greater risk of moulds and bacteria, and can have reduced energy and vitamin levels, especially A, D3, E, K and thiamine3. Conduct feed tests on heated grains prior to feeding to cattle.

Benefits

Heated or sprouted grains can be added into rations providing similar results as conventional feed grains. They must be incorporated slowly; animals must be monitored for any digestive upset or signs of acidosis. Heated or sprouted grains can often be purchased at a further discount to feed grains.

Drawbacks

Storage of these grains can be difficult due to the high moisture content and potential for heating or spoilage. The ideal moisture level for grain storage is under 14%. Sprouted grains are often over 16% moisture. These grains can be stored in aeration bins to dry them down and reduce moisture for safe storage. Ensiling in bags or silos to exclude oxygen is another storage option.

High moisture or sprouted grains are at higher risk of containing moulds and mycotoxins such as ergot or vomitoxin, which can cause problems including decreased animal performance, fertility issues and abortions. While cattle are able to consume some levels of mould and mycotoxins, feed testing is vital to ensure that the levels are within safe parameters. Consistency of product can also be a concern.

Most suitable for:

Mature dry cows, feeders, yearlings.

Use caution with:

Bred heifers, pregnant cows, cow-calf pairs.

The above photo is a blend of rolled barley, with a smaller percentage of high moisture, heated durum. Photo credit, T. Carter.

Straw

Straw can be an affordable alternative feed for beef cattle.Cereal straw, such as barley, oat, and wheat, is palatable and producers report feed test results with averages of 4% CP and 45% TDN. Legume straw is generally higher in protein, at 7-8% CP, with a similar TDN as cereal straw. These low protein and energy levels will not meet the nutritional needs of young, growing calves, yearlings, or lactating cattle, so supplemental feed is required.

While harvesting equipment has changed over the past decade to finely chop and distribute most crop straw residue across the field during combining, opportunities still exist to drop, windrow and bale the straw when harvesting cash crops. When weather events, such as hail or drought occur, cash crop farmers may be willing to sell straw to livestock producers as there may not be sufficient mature crop to warrant harvesting.

Benefits

Straw can often be purchased for competitive prices. Mixed farming/ranching operations can bale crop residue. Producers have flexibility to feed or use for bedding.

Drawbacks

Straw is high in fibre, but low in protein and energy. If cattle do not have their energy requirements met, they may over consume straw and become impacted. Use of straw requires feed tests, mineral supplementation and additional grain, pellets or other alternative feed sources to meet cattle’s nutritional needs.

Most suitable for:

Mature, dry cattle, when straw is incorporated into a ration containing additional protein and energy. Most useful for stretching feed supplies, as the low energy and protein levels are not suitable as a stand-alone feed source, particularly during cold weather when cattle’s energy needs increase.

Use caution with:

Growing calves, bred replacement heifers, second calvers, lactating cattle, or cattle in second or third trimester of pregnancy. Straw as part of the diet will need to be carefully supplemented with higher nutrient feed sources to ensure a properly balanced ration.

In the photo on the left, lentil straw is rolled out and fed as part of this alternative feeding program. Cattle received greenfeed oat/pea bales, lentil straw bales and some screenings, as well as access to native pasture, as calculated by CowBytes software to ensure adequate protein, energy, fibre and minerals. The photo on the right shows the feed well cleaned up and consumed by the cattle. Photo credit, T. Carter.

Sugarbeet – Pulp, Tops, Tailings

Sugarbeets can be fed as pulp, tops, and whole. They are an excellent source of energy with whole beets having a TDN of up to 81% and pulp usually at least 70% TDN. Tops and tailings are a bit lower, ranging from 50-65% TDN. Beet by-products are a low source of protein at 6-9%, requiring supplemental protein in the ration1. Sugarbeet pulp is a by-product of sugar extraction and the digestible fibre, rather than the starch, provides a relatively high energy feed source. Sugarbeet pulp can be incorporated into a ration, fed in bunks, or used as a supplement on pasture to reduce forage consumption or can be stored in a bag, bunker, or ensiled to reduce oxygen and risk of spoilage2. Whole beets can be stored in a pile during cold months but should be used prior to warm weather to avoid spoilage. Ensiling along with dry ingredients, such as straw or hay, provides longer-lasting storage options.

Benefits

The nutrient profile of sugarbeet pulp is similar to corn silage and can be used as an energy supplement, as well as in backgrounding and finishing rations.

Drawbacks

Both pulp and whole sugarbeets are bulky, therefore transportation costs may be prohibitive unless the source is close by. They may require additional efforts for proper storage, as well as for mixing and processing. Whole beets can be a choking hazard for cattle, so it is recommended to process or break up prior to feeding. Beet tops contain oxalates, so should be fed in low levels to avoid scouring and potential liver or kidney problems. Sugarbeets and beet pulp are high in rapidly digestible carbohydrate; ensure gradual addition to the diet, do not overfeed, and provide a fibre source to avoid acidosis.

Most suitable for:

Dry cattle, backgrounding or finishing.

Yellowfeed

Yellowfeed is produced when an annual cereal crop, such as barley or oats is sprayed with glyphosate and left to dry standing in the field. Once dried, it can be cut, baled and used as feed. Producers target to spray the crop five days earlier than if it was cut for greenfeed. The crop grows for several days before drying down, resulting in a small increase in yield. Approximately 15 to 21 days later, the crop is dried down, ready to swath and bale. Oats are best sprayed at the milk-dough stage and barley at the soft dough stage. Barley dries down four to seven days faster than oats3. Crude protein and energy levels can be variable.

Benefits

Yellowfeed is a palatable feed source that can be sprayed, cut and baled within a shorter window than greenfeed. Kernels and leaves remain intact. Weathering losses in windrows are reduced and baling can occur immediately after swathing. This may be attractive to crop farmers who have suffered a loss due to drought or hail as they can get an otherwise unharvestable crop off the field in a timely manner with the additional benefit of perennial weed control. Producers battling weather challenges have the ability to spray, cut and bale good quality feed during a shorter time period.

Drawbacks

Variability in protein and energy levels may require additional supplementation. The use of glyphosate prevents regrowth for potential fall grazing. Yellowfeed is best cut with a swather, rather than a mower conditioner, to prevent shattering the dried leaves and stems, so will require additional machinery or custom swathing costs.

Most suitable for:

All classes of cattle.

Weeds

Weeds must be cut and baled at an early stage to capture feed value and ensure palatability. For example, young kochia, cut before flowering, is palatable and has a nutrient value similar to alfalfa with protein levels up to 20%. It does, however, have a laxative effect on cattle due to the high mineral salts. Young cattails have poor feed value, similar to straw, but could be used to supplement other feed sources.

Benefits

Cutting and baling weeds prior to seed set can be an effective means of weed control, particularly with glyphosate-resistant kochia. Some farmers may be willing to let livestock producers cut and bale weeds to remove them from their fields. Cutting and baling cattails may also hold some appeal for cash crop farmers who want to remove plant material prior to cultivating or disking down a slough that has dried up. Weeds and cattails can usually be procured at little to no cost. Transportation and storage costs are similar to other cut and baled feedstuffs.

Drawbacks

If weeds are allowed to set seed prior to cutting and baling, the cattle may distribute the seeds over the entire area that they are being fed in, potentially introducing undesirable, weedy species to new areas. Ensure that any weeds cut and baled as feed have not set seed prior to baling. Many weeds accumulate nitrates and could be toxic to cattle. Kochia contains oxalates, which can impair liver and kidney function. While cattails have a feed value of approximately 6% protein when young, mature cattails have no feed value and are not palatable to cattle.

Most suitable for:

Dry, mature cows, yearlings.

The following table is a summary of the nutrient content of many alternative feeds. Note that the values should be considered as a guideline only and may not be representative of individual samples due to the significant variability in alternative feeds. Producers are encouraged to conduct feed tests on alternative feeds to ensure that a safe and balanced feeding program is developed.

Figure 1 – Nutrient Content of Alternative Feeds.

Conclusion

Livestock producers continually look for ways to reduce feed costs while maintaining condition and health of their herds. Sourcing local alternative feeds can be an effective way to achieve these goals. The alternative feeds available will be highly regional and often the quality or supply is variable. Alternative feeds require careful management to ensure that they meet the nutritional needs of the cattle. Additional protein, energy or fibre sources may be necessary to create a balanced ration.

Some of these alternative feeds may contain low levels of dry matter, energy, protein, fibre, vitamins or minerals, while others may have a tendency to accumulate toxins, have excess mineral content causing antagonisms with other minerals, or contain other anti-nutritional factors that may impact animal health. Feed testing and analysis by a livestock nutritionist or specialist is strongly recommended to create a safe ration. Variability and consistency between alternative feeds and even between loads of the same feed can create additional management challenges. Consider the costs of transportation, storage, additional handling or processing, and the impact on livestock health and performance. Software programs such as CowBytes, can be a useful tool to input feed analysis, compare costs, and create a balanced ration that can reduce costs and stretch feed supplies while maintaining a proper nutrition program.

Always introduce new feeds slowly to allow cattle time to adjust. Avoid issues with compromised rumen health or acidosis by making feed changes slowly over two to three weeks and monitoring cattle carefully for potential problems created by the alternative feed. Using alternative feed sources can reduce costs, lessen risk in procuring feed and provide additional sources of the key feed nutrients required.

- References

-

- Saskatchewan Ministry of Agriculture. Beef Cow Rations and Winter Feeding Guidelines.

- Canola Council of Canada. 2015. Canola Meal Feeding Guide, 5th Edition.

- Lardy, G. 2015. Alternative Feeds for Ruminants. AS1182. North Dakota State University.

- Alberta Ministry of Agriculture. Salvage Canola Crops Can Make Good Cattle Feed.

- Drovers. 2017. Drought-stressed Canola Possible Forage for Livestock.

- Manitoba Agriculture. Increasing Cow/calf Profitability Using Chaff and Chaff/Straw Feedstuffs.

- Lundy, E.L. and D. Loy. 2014. Ethanol Coproducts for Beef Cattle: The Processes and Products. Iowa Beef Centre, Iowa State University Extension and Outreach Factsheet IBCR 200A; NASEM 2016.

- New Brunswick Agriculture. Feeding Potatoes to Cattle.

- McAllister, T., W. Yang, Y. Wang, M. Swift, and D. Gibb. 2014. Replacing barley grain with wheat and grain screenings in feedlot diets. Alberta Crop Industry Development Fund Ltd.

- Mustafa, A.F. 2002. Ruminal Fermentation and Utilization of Unconventional Feeds in West-ern Canada. McGill University.

- Wahlberg, M. 2009. Alternative Feeds for Beef Cattle. Virginia State University.

- Lardy, G. 2017. Feeding Value of Sprouted Grains. AS647, North Dakota State University.

- Manitoba Agriculture. Spoiled Feeds, Molds, Mycotoxins and Animal Health.

- Ontario Ministry of Agriculture, Food and Rural Affairs. 2013. Sugar Beets as a Feed Ingredient.

- Jenkins, K. H. 2014. Using Sugarbeet Pulp in Rations for Beef Cows. University of Nebraska Lincoln.

- May, W.E., L. Klein, and G. Lafond. Yellowfeed production in Saskatchewan. Agriculture and Agri-Food Canada, Saskatchewan Agriculture.

Feedback

Feedback and questions on the content of this page are welcome. Please e-mail us.

Expert Review

This content was last reviewed January 2020.

This content was last reviewed August 2023.